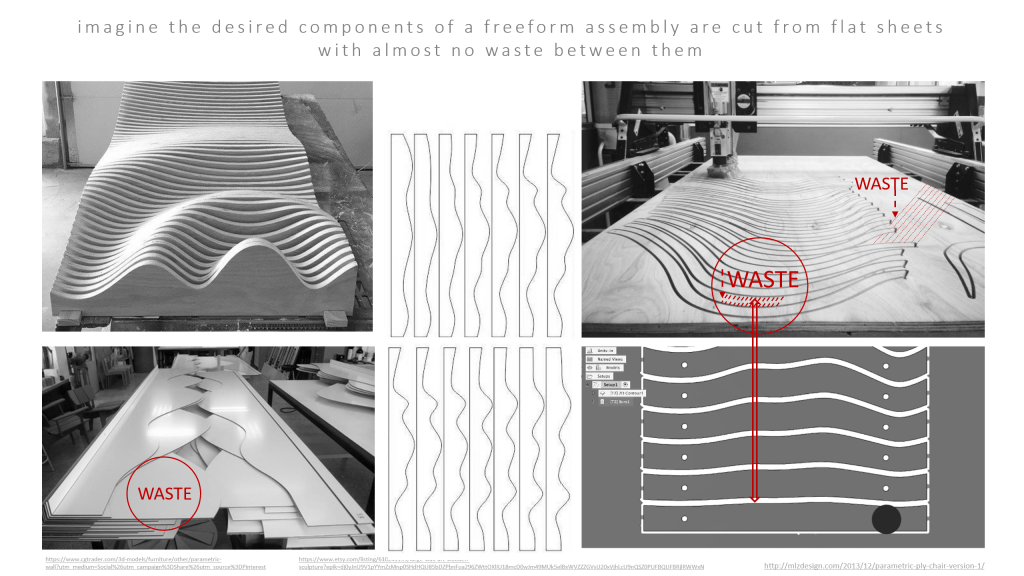

2D Nesting

Minimum Waste Construction

2020-2022 | transLAB, Advanced Studio: Embedded Intelligence & CCA Digital Craft Lab, San Francisco. .

Collaborators: Borhani

Links: Nesting Fabrication

Project Description: Nesting Fabrication Method

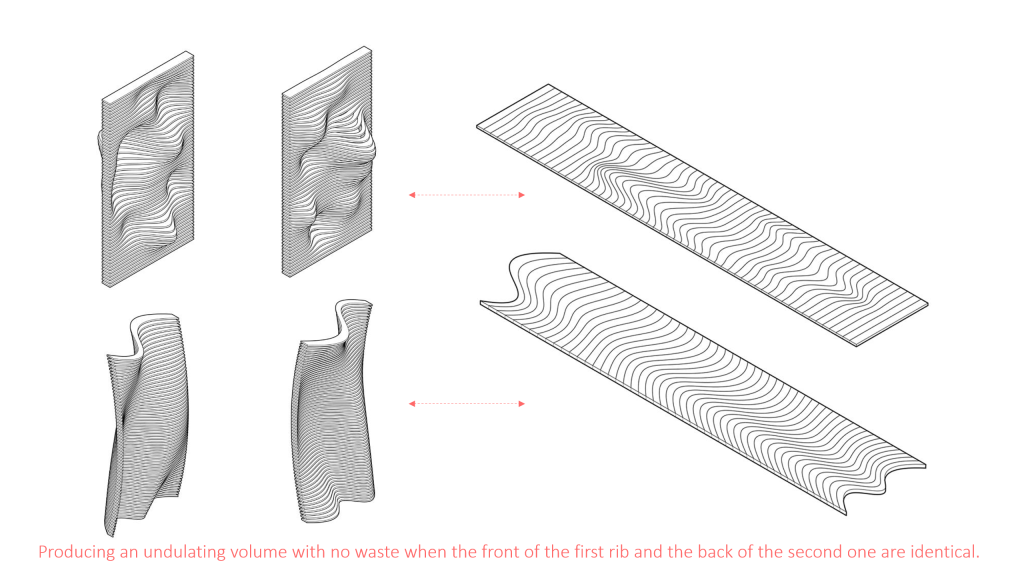

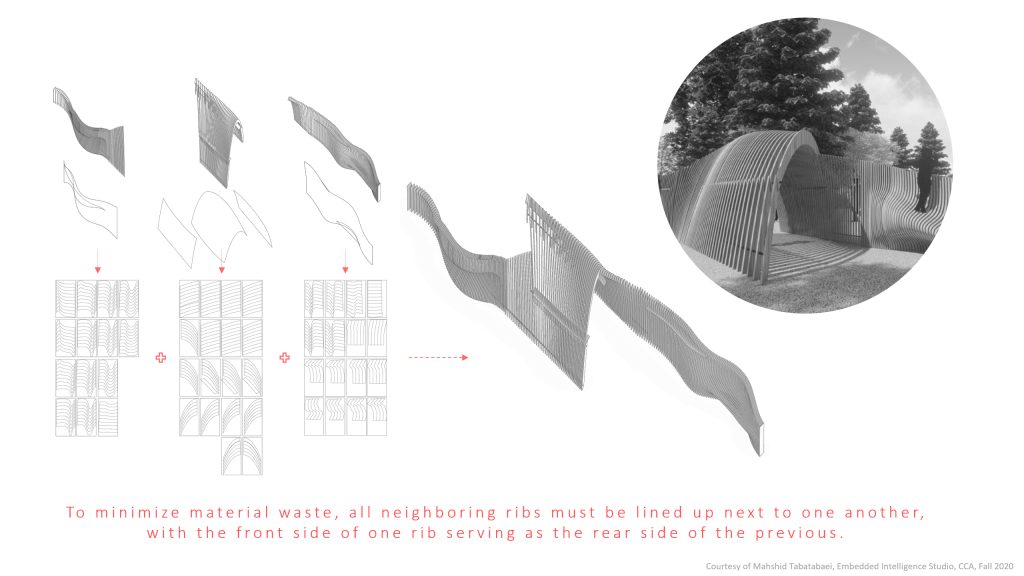

In this research, the term “nesting” refers to a geometric strategy that transforms a freeform volume into stackable components, enabling efficient fabrication, assembly, and transportation. A nested assembly begins with the subdivision of a volume into identical yet interrelated parts. These parts are then reorganized to nest together—either side by side (horizontally) or vertically stacked—forming a compact arrangement of tightly fitting elements (Figure 3). Each nested part belongs to a greater whole, where one side is geometrically compatible with the adjacent side of its neighbor.

This work introduces three nesting approaches based on different levels of geometric control: 2D, 2.5D, and 3D nesting methods.

2D Nesting Method

The 2D nesting method is a design-to-fabrication strategy used to construct undulating walls or ceilings using parallel, rib-like components. These elements are CNC- or laser-cut from flat sheets with minimal material waste. Each rib shares curvature logic with its neighbors, and the overall geometry defines both the front and back of the form (Figure 4). By adjusting a few key parameters—such as material thickness, number of ribs, and spacing—a custom parametric model in Grasshopper generates both a 3D digital form and its corresponding 2D cut files.

To optimize material usage, ribs are aligned side-by-side, where the front face of one rib serves as the back face of the previous. The resulting cutting layout consists of adjacent profiles with shared edges and no gaps, maximizing sheet efficiency. Aside from minor losses due to the cutting tool’s kerf width, no material is wasted. Because each pair of ribs is generated through just three cutting operations, this method also reduces matching and assembly time.