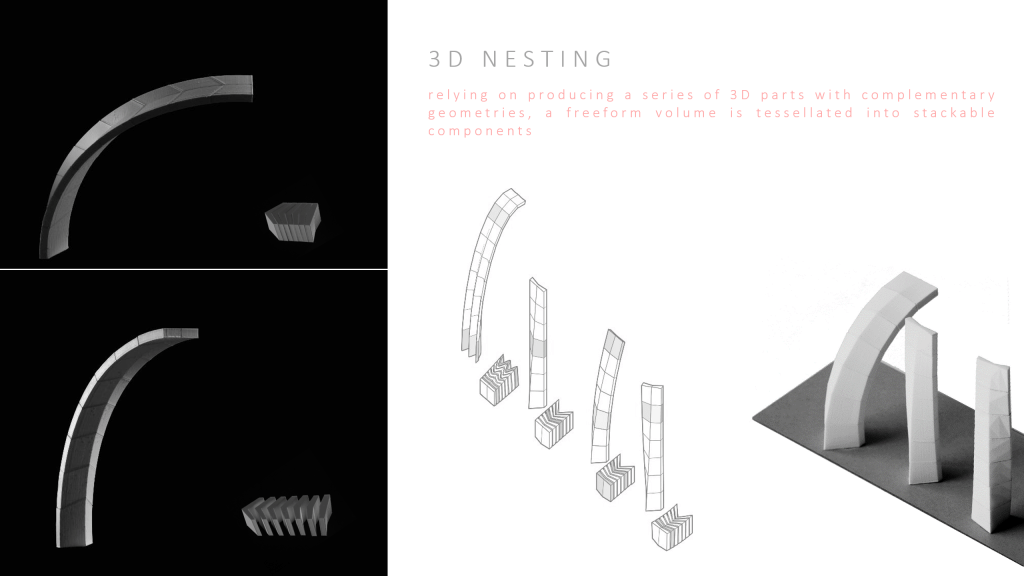

3D Nesting

Minimum Waste Construction

2020-2022 | transLAB, Advanced Studio: Embedded Intelligence & CCA Digital Craft Lab, San Francisco.

Collaborators: Borhani

Links: Nesting Fabrication

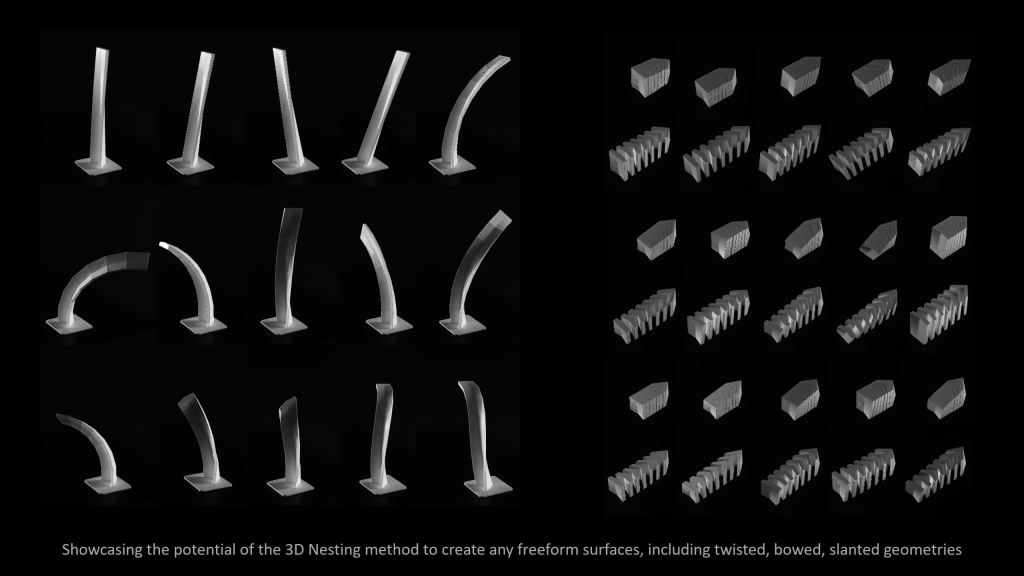

Research Description: 3D Nesting Method

The 3D nesting method is a fabrication strategy that divides complex volumes into stackable, interlocking components. Using non-parallel slicing planes, it produces wedge-shaped or voussoir-like elements that fit together tightly, improving both structural integrity and packing efficiency.

Unlike 2D or 2.5D methods, 3D nesting allows for more complex geometries by adapting slicing planes—twisted, slanted, or rotated—to match the form. This makes it possible to nest components of varying shapes into compact stacks for easier transport and assembly.

The method requires careful coordination of geometry, material behavior, and tool compatibility. When designed effectively, 3D nesting supports modular, large-scale construction with minimal waste and maximum spatial efficiency.