Clay++ | 3D Printing on Arbitrary Surfaces

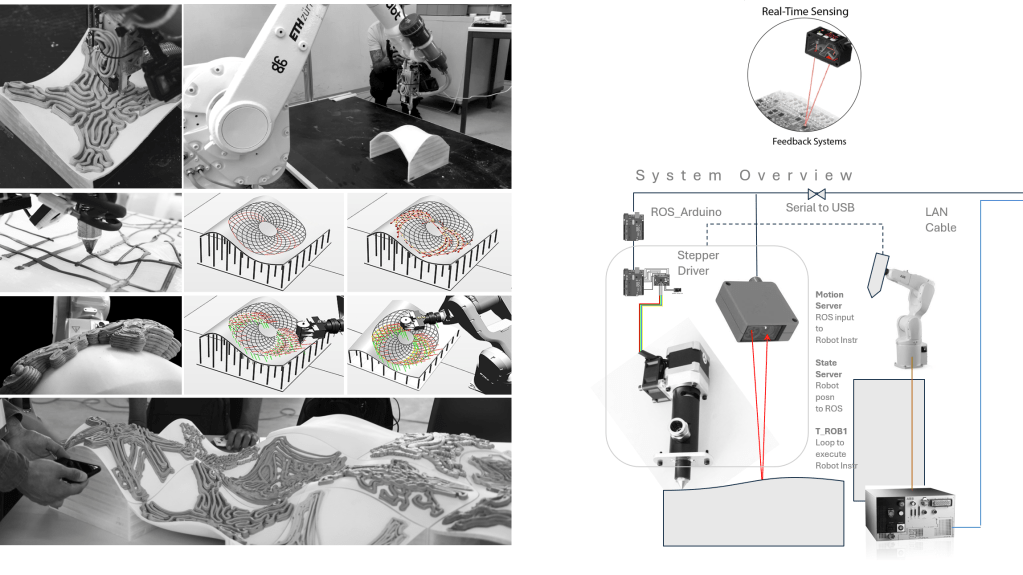

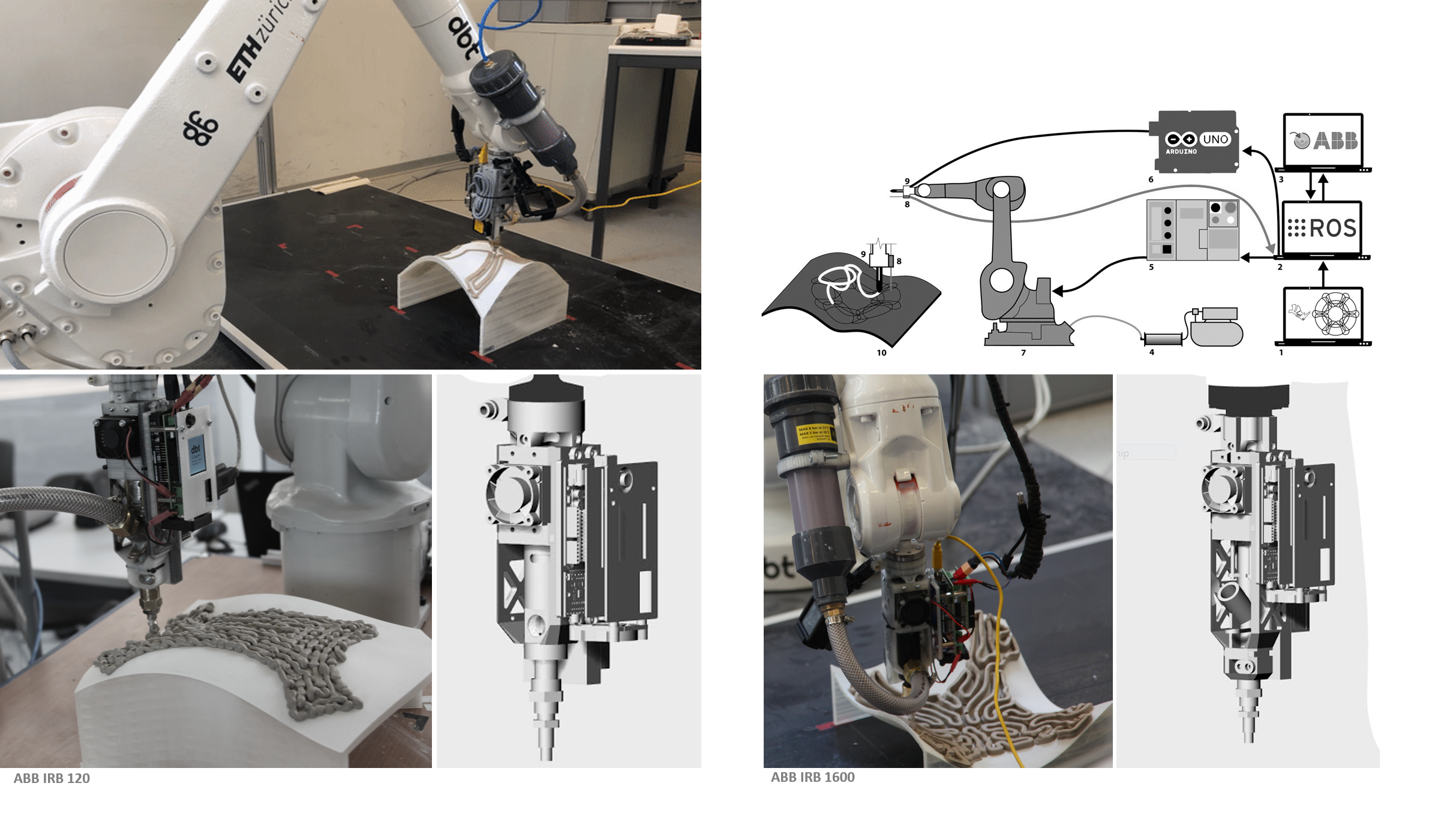

REAL-TIME FEEDBACK IN ROBOTICS |Hardware & Software Development

2018 | RobArch – ETH, Zurich.

Collaborators: Anton, Hyunchul (ETH), Shell, Varghease & Palmer(Texas A&M)

Links: RobArch2018

Project Description: Uneven shrinkage in paste-based materials like clay or concrete occurs due to uneven moisture loss or curing, leading to warping, cracking, layer delamination, and reduced structural integrity. To address this, we developed a sensing-oriented control system with distance measurement hardware for on-site robotic 3D printing. This system continuously measures layer height and alignment, enabling dynamic adjustments to the robotic arm’s path, deposition rates, and layer thickness. These real-time corrections ensure precise deposition, uniformity, and reduced stress concentrations. Our workflow integrates real-time sensing, surface mapping, and adaptive toolpath generation, enabling printing directly onto non-planar or irregular geometries without pre-modeled designs, much like to tattooing patterns onto 3D surfaces.