Non-Planar Robotic Printing

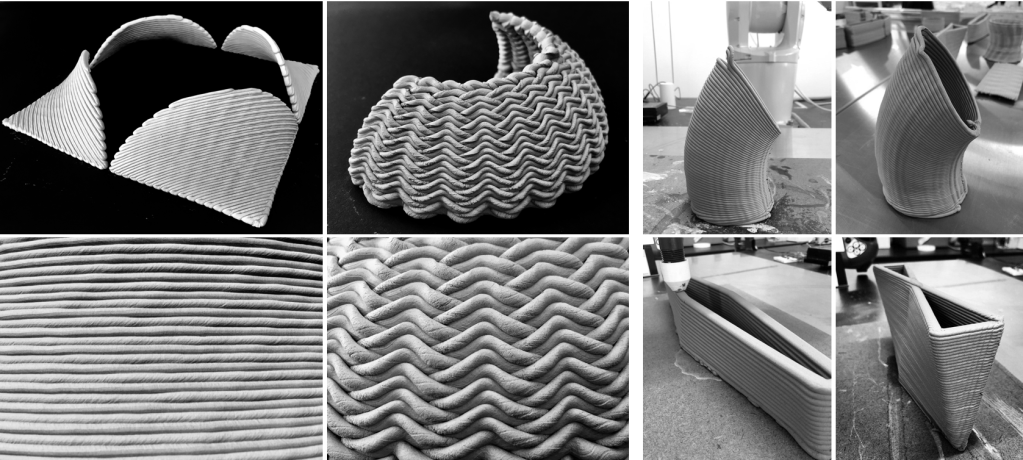

Exploring Scaffold-Free Shell Structures

Funding| X-Grant: ROBOTIC CLAY 3D PRINTING PARAMETERS

2019 | Autodesk Technology Center, San Francisco, Texas A&M.

Collaborators: Mehdi FarahBakhsh (PhD researcher)

Links to publications: Impact of Robotic 3D Printing Process Parameters on Bond Strength

Impact of robotic 3D printing process parameters on interlayer bond strength

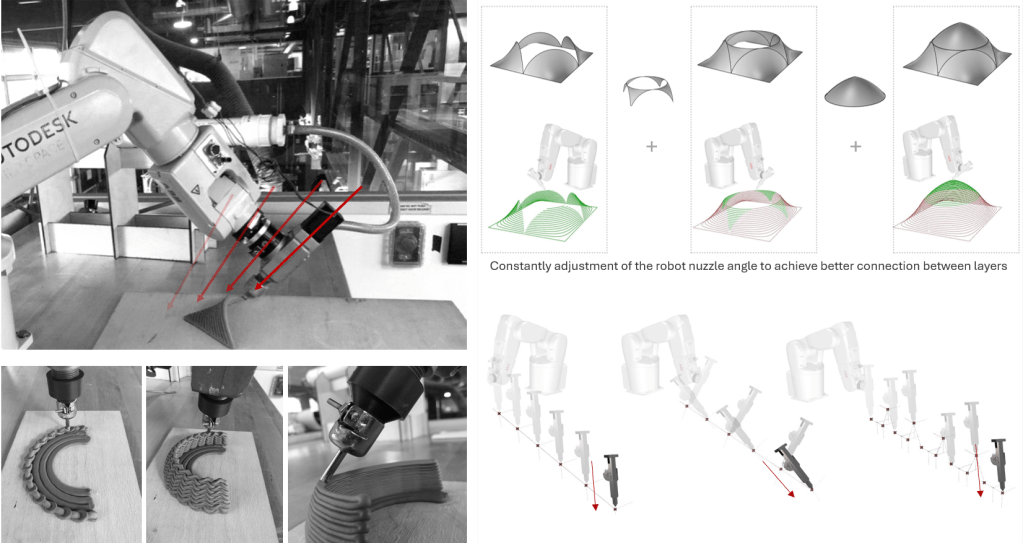

Project Description: Combining our findings at the Mezzo level with Micro-level paste printing techniques, we developed a workflow to print without scaffolds by constantly adjusting the nozzle angle to improve layer connections. In addition to adjusting printing parameters at the Mezzo scale, we also explored the optimal geometric characteristics at the Macro scale and how to subdivide surfaces for different printing parameters. This approach helped eliminate the need for supports while strengthening the overall structure.