PRINT in PRINT | Dissolvable Formwork

Nested 3D Printed Shell Structures

2020 | Texas A&M + Autodesk Technology Center, San Francisco.

Collaborators: Farahbakhsh & Borhani.

Links: PRINT in PRINT

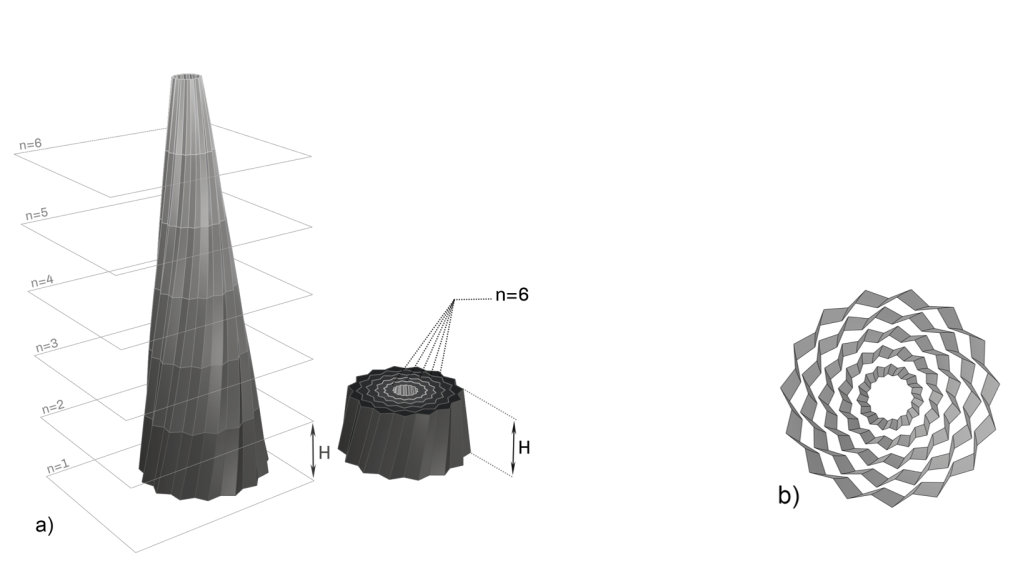

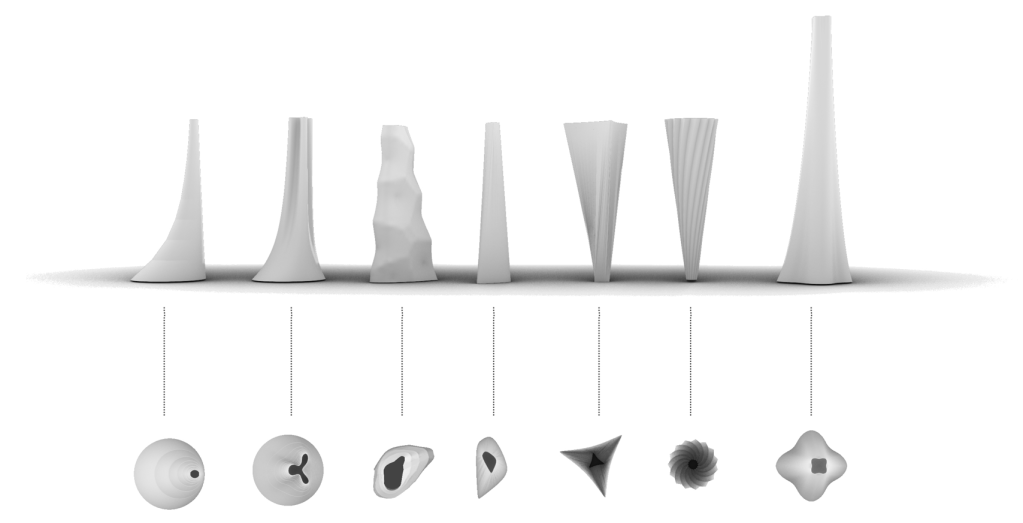

Project Description: In this project, we delved into the potential of 2.5D nesting for robotic printing to reduce the use of any secondary material or external support that would need to be removed in a post-processing operation. Here, we explored the fundamental of 2.5 D nested construction to design volumes with concave or convex geometry. These volumes were made from a series of components printed in stacks. We called this fabrication approach, “PRINT in PRINT” while using robotic clay printing.

This research also introduced a new application for clay where it is used as a temporary formwork for concrete. Fresh concrete placed adjacent to clay absorbs clay’s moisture over time, and consequently, the clay parts dry faster than air-drying. The fast-drying process results in a cracked and shattered surface on the clay that can be easily removed by hand, pressure washed, or dissolved in water.

This is similar to water-soluble materials used for temporary supports in 3D printing with plastic-based materials