Robotic Clay Printing

Impact of Robotic 3D Printing Process Parameters on Bond Strength

2019 | Autodesk Technology Center, San Francisco, Texas A&M.

Collaborators: Mehdi FarahBakhsh (PhD researcher)

Links to publications: Impact of Robotic 3D Printing Process Parameters on Bond Strength

Impact of robotic 3D printing process parameters on interlayer bond strength

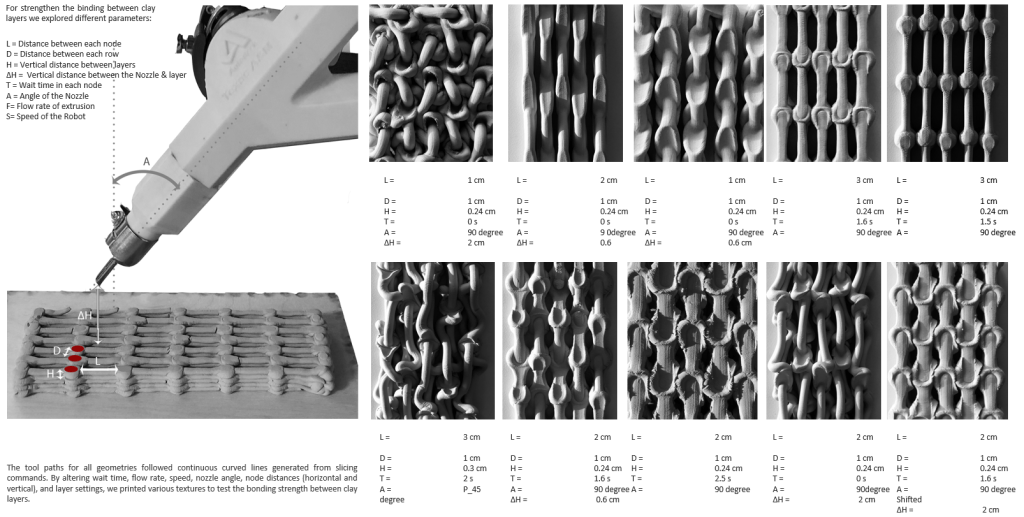

Project Description: To strengthen the binding between clay layers, we focused on three scales: Micro, Mezzo, and Macro. The core of this research was to explore how fine-tuning printing parameters at the Mezzo scale could achieve varying structural strengths and surface patterns. By adjusting flow rate, speed, waiting time, and layer spacing, we were able to create different strengths and textures. To maintain consistent and controllable flow rates, we designed and tested various augers to optimize printing quality.